Roof sandwich panels MWS

Description

The construction of a low-slope roof is a time-consuming process: laying vapour barrier, insulation, roofing mat – all these activities require a lot of work and constant quality control. The purchase of roofing sandwich panels allows you to have a ready-made roof at once.

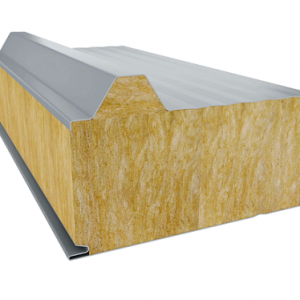

Non-combustible roof sandwich panels WMS represent a three-layer construction, which consists of:

– The bottom layer is a steel galvanised corrugated sheeting that takes the snow load of the building’s covering and the roof’s own weight. The bottom side can be painted;

– The middle layer is a non-flammable mineral wool insulation, the thickness of which is determined by the thermal engineering calculation, depending on the climatic conditions of the building area;

– The top layer – steel galvanised corrugated deck.

Features and application

The panels are connected to each other by overlapping the corrugation of the upper lining on the panel located next to it. The sheets are joined together by rivets, and the panels are attached to the purlins of the coating by self-tapping screws installed in the upper corrugation of the outer layer and passing through the entire thickness of the roofing “pie”.

The installation of sandwich roof panels makes it possible to close the space of a building under construction against precipitation in a very short time, and the purchase of wool mineral standatr panels – with a mineral wool insulation allows to secure the roof against fire.

Panexus offers WMS sandwich roof panels with mineral wool insulation of the required length so that the structure covers the entire length of the roof slope, thus avoiding transversal joints.

Panexus’s purchase of non-combustible WMS sandwich roof panels with mineral wool insulation makes it possible to roof a large building in a matter of days.