ADVANTAGES OF PU SANDWICH PANELS:

Strong heat isolation

Strong heat isolation High level of fire resistance

High level of fire resistance High density

High density Weather resistance

Weather resistance Design flexibility/simplicity

Design flexibility/simplicity Easy superficial cleaning

Easy superficial cleaning Construction lightness (building opportunity without the foundation in several cases)

Construction lightness (building opportunity without the foundation in several cases) Materials multiple usage ability

Materials multiple usage ability Stands out for economy of construction (does not need additional repair working)

Stands out for economy of construction (does not need additional repair working)

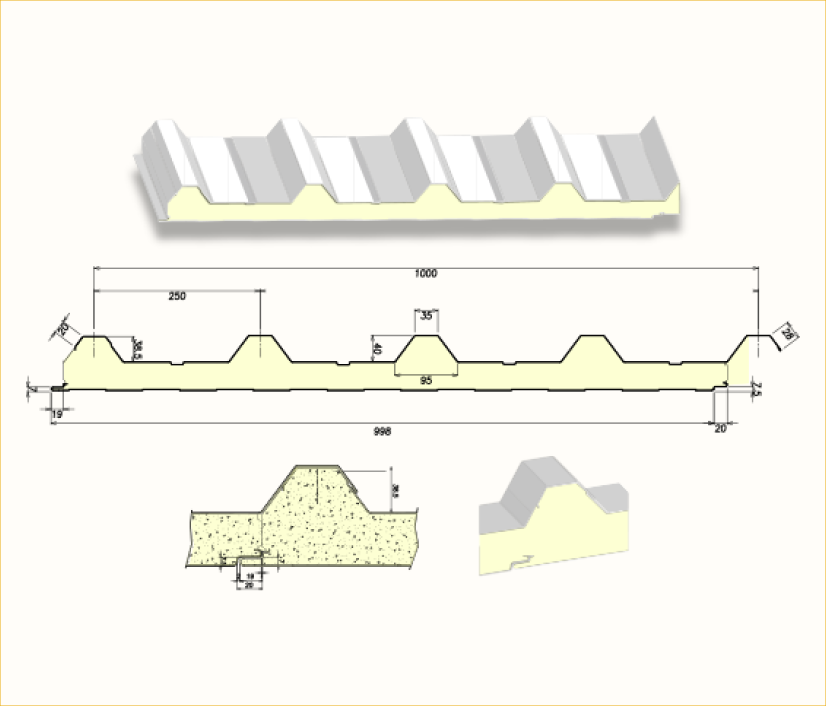

TECHNICAL DETAILS

APPLICATIONS

For roofs

DIMENTIONS

Width: 1000 mm, Length: max 15 m

CORE MATERIAL

Polyurethane (PUR), Rockwool (RW), Expanded polystyrene (EPS)

POLYURETHANE THICKNESS

40-50-60-70-80-100-120-150 mm

UPPER SIDE COVER MATERIALS

Prepainted galvanized steel with protective layer

POLYURETHANE DENSITY

40 (+-2) kg/ m3

LOWER SIDE COVER MATERIALS

Polyurethane (PUR)

THICKNESS OF METAL SHEET

0.35- 0.60 mm

DESIGN

White grey. Other available

FLAMMABILITY CLASS

B2

| mm | Weight kg/m² | Heat Transfer Efficiency W/m²K | Purlin distance | |||||

|---|---|---|---|---|---|---|---|---|

| 1.05 m | 1.4 m | 1.75 m | 2.1 m | 2.45 m | 2.28 m | |||

| 50 | 9.740 | 0.44 | 595 kg | 407 kg | 297 kg | 221 kg | 174 kg | 148 kg |

SANDWICH PANEL CATALOGUE

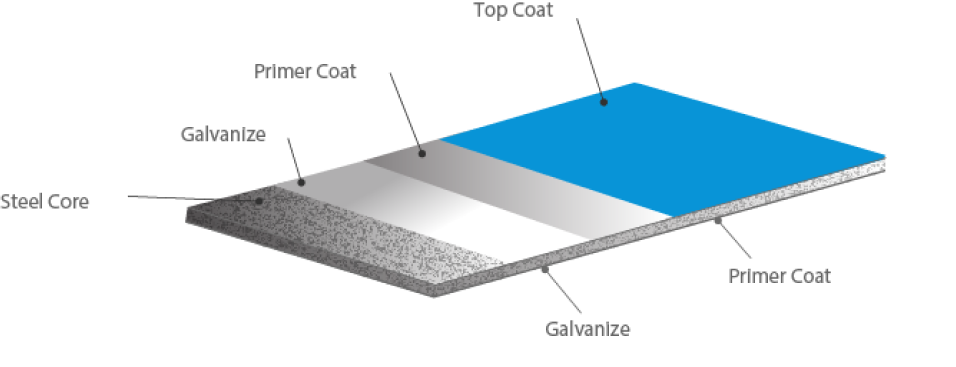

CONSISTENCE

Sandwich panel metal surface consists of galvanized iron sheet and organic covering.

Organic covering is characterized with corrosion stability that contributes long service life of the material.

According to the corrosion type upper site metal cover of sandwich panel consists of: organic layer 25µm and galvanized layer 20 µm that can be raised up to 200 µm upon requirements

PREPAINTED GALVANIZED SHEET IRON

Panex uses prepainted galvanized sheet iron in coils that is produced according to ECCA

(The European Coil Coating Association) standards.

| Sheet iron mark | DX51D + Z | EN 10327 |

|---|---|---|

| Thickness tolerance (0,35 mm < iron thickness 0,6 mm) | +0.05 mm | EN 10143 |

| Tensile Strength | 500 (max.) | EN 10327 |

| Elongation,% | 22 (min.) | EN 10327 |

| Paint amount | 100-275 gr/m | EN 10327 |

| Paint typet | Polyester Polyester, PVdf, Plastisol, PVC, Polyurethane etc | EN 10327 |

POLYURETHANE SOLID FOAM

In sandwich panels we use polyurethane foam with the best heat isolation performance. Polyurethane foam is waterproof material and has antibacterial characteristics.

| Density | 40 (+2) kg/m³ | EN 1602 |

|---|---|---|

| Thermal conductivity ratio | 0.022 – 0.024 W/mk | EN 13165 |

| Closed cell percentage | 95% | EN 14509 |

| Steam diffusion | 30-100 | EN 12086 |

| Stability in sizes | Level DS(TH)11 | EN 13165 |

| Stability to pressure (Mpa) (10) | min. 0,095 | EN826 |

| Water absorption (vol. %) | 2% (168 hours) | Producer method |

| Usage tem. margins (° C) | -200/+110 (° C) |

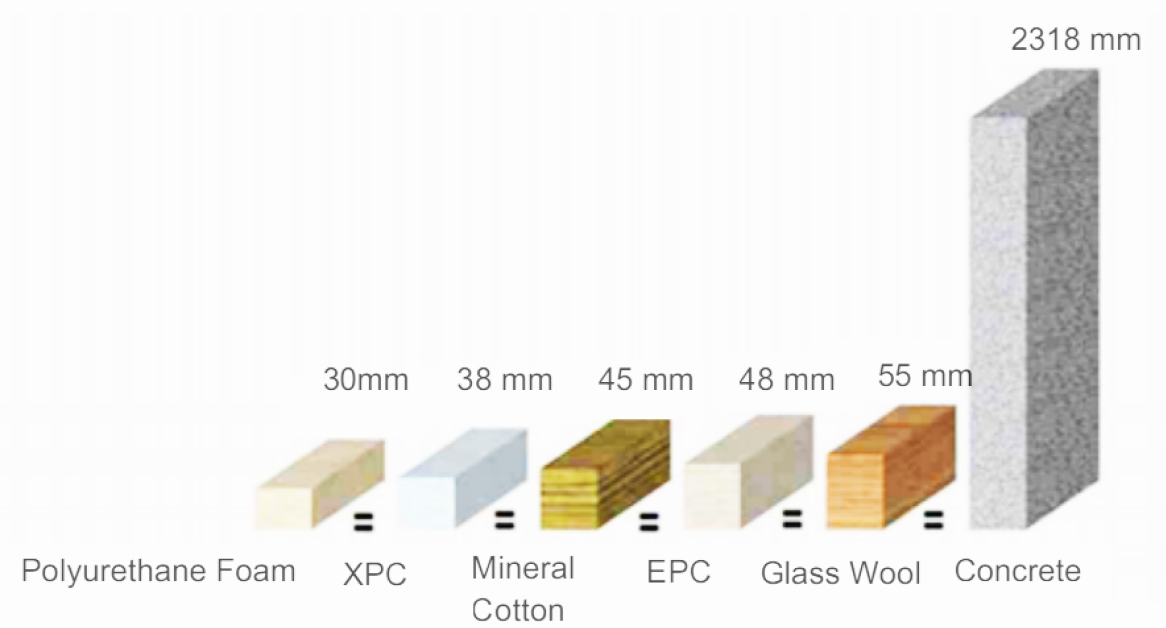

HEAT ISOLATION

To achieve the desired results in case of low thermal insulation materials it is necessary to

increase material thickness. While in case of polyurethane foam the minimum thickness of

material is remained.

According to thermal insulation values, multifunctional usage and exploitation durability, today polyurethane foam is the optimal solution.

THERMAL CONDUCTIVITY VALUE

| Panel thickness | Thermal conductivity U(W/m2) | Thermal conductivity U (KCAL/m2) |

|---|---|---|

| 40 mm | 0.4973 | 0.4276 |

| 45 mm | 0.4468 | 0.3842 |

| 50 mm | 0.4056 | 0.3488 |

| 60 mm | 0.3424 | 0.2944 |

| 80 mm | 0.2611 | 0.2245 |

| 100 mm | 0.2110 | 0.1814 |

| 120 mm | 0.1771 | 0.1522 |

| 150 mm | 0.1426 | 0.1226 |

MECHANICAL STABILITY

Lifting capacity is an important issue while sandwich panel selection for the specific building. Factors such as own weight, wind load, snow load and temperature can effect on building as together as separately.

Sandwich panel consistent metal sheets and fillers between these two sheets have low lifting capacity but composition which is made by these materials is a new system and its lifting capacity is compatibly improved.

MECHANICAL STABILITY

Lifting capacity is an important issue while sandwich panel selection for the specific building. Factors such as own weight, wind load, snow load and temperature can effect on building as together as separately.

Sandwich panel consistent metal sheets and fillers between these two sheets have low lifting capacity but composition which is made by these materials is a new system and its lifting capacity is compatibly improved.

FIRE RESISTANCE RATING

PUR material is effective while fire. Polyurethane foam with its chemical coponents can reduce and prevent fire from spreading that increase product efficiency.

Panex polyurethane panels are classified with B2 fire resistance rate (based on TS EN 14509 standarts)

Stability in sizes while heating

+100 C° PUR

Inflammation temperature

+285 C° PUR

FIRE RESISTANCE RATING

PUR material is effective while fire. Polyurethane foam with its chemical coponents can reduce and prevent fire from spreading that increase product efficiency.

Panex polyurethane panels are classified with B2 fire resistance rate (based on TS EN 14509 standarts)

Stability in sizes while heating

+100 C° PUR

Inflammation temperature

+285 C° PUR

SOUND ISOLATION

SOUND TRANSFER LOST ACCORDING TO FREQUENCY

| PUR | Frequency (Hertz) | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| kal | 125 | 160 | 200 | 315 | 400 | 500 | 630 | 800 | 1000 | 1250 | 1600 | 2000 | 2500 | 3150 | 4000 | 5000 | 6300 | 8000 |

| 50 mm | 7.3 | 9.3 | 11.7 | 11.4 | 12.3 | 13.3 | 14.41 | 14.7 | 15.9 | 15.3 | 11.5 | 11.8 | 23.4 | 29.2 | 32.4 | 29.8 | 32.5 | 36.9 |

| 60 mm | 8.1 | 22.1 | 14.2 | 13 | 13.9 | 13.8 | 14.6 | 15.3 | 16 | 15.3 | 13 | 18.3 | 24.2 | 29.2 | 32.5 | 29.8 | 32.5 | 36.9 |

SOUND ABSORPTION RATIO ACCORDING TO CHANGE FREQUENCY

| PUR | Frequency (Hertz) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| kal | 315 | 400 | 500 | 630 | 800 | 1000 | 1250 | 1600 | 2000 | 2500 | 3150 | 4000 |

| 50 mm | 0.08 | 0.11 | 0.22 | 0.2 | 0.05 | 0.59 | 0.09 | 0.11 | 0.04 | 0.07 | 0.18 | 0.07 |

| 60 mm | 0.14 | 0.21 | 0.25 | 0.25 | 0.06 | 0.69 | 0.12 | 0.12 | 0.22 | 0.08 | 0.2 | 0.11 |